The research group of Professor Jiang Hong of the University of Science and Technology of China and the research group of Professor Yu Hanqing successfully prepared high-calorie and stable solid-phase bio-coal and high-calorific value, respectively, by coupling rapid pyrolysis, atmospheric distillation and chemical vapor deposition High-performance carbon nanomaterials (small layers of graphene and carbon nanotubes) provide important technical support for the commercial application of waste biomass pyrolysis technology. The result was published in "Science Progress" a few days ago.

Waste biomass is both an environmental pollutant and a renewable raw material. Pyrolysis is one of the important technologies for waste biomass utilization. Through the pyrolysis of biomass under anoxic conditions, renewable bio-oil, bio-char and a part of pyrolysis gas can be obtained. However, there are currently two key issues that seriously hinder the commercial application of pyrolysis technology. One is that pyrolysis bio-oil is unstable and prone to aging and deterioration, and its composition is difficult to separate and upgrade. Market Competitiveness.

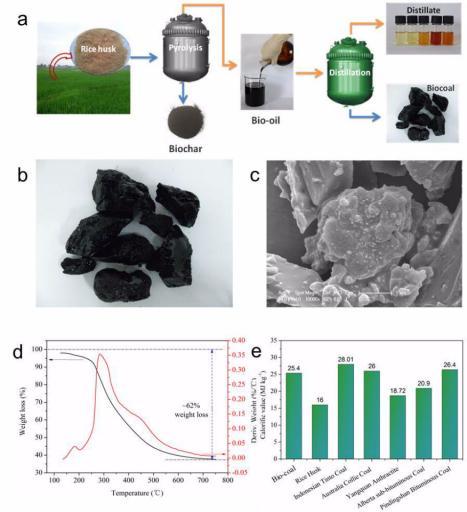

Biological coal preparation route and products

Bio-oil obtained by pyrolysis of biomass raw materials (agricultural and forestry wastes and organic solid wastes, etc.) is a renewable resource. Researchers at home and abroad have been working on the catalytic upgrading and separation of bio-oils, hoping to obtain High value-added chemicals or high-quality fuel. However, the composition of bio-oil is complex and unstable, and usually contains hundreds of organic compounds. In the catalysis process, some organic substances undergo condensation, dehydration, coking and other reactions, which lead to the failure of the catalyst and make the catalytic upgrading process difficult to continue. At the same time, common separation methods, such as atmospheric distillation or molecular distillation, cause the bio-oil to coke quickly, which hinders the distillation from proceeding further. The research group found that a new solid fuel (named bio-coal) can be obtained by controlling the parameters of atmospheric distillation process to achieve rapid coking of bio-oil. Analysis shows that the calorific value of bio-coal obtained from different biomass raw materials (rice husk, sawdust, wheat straw, bagasse, soybean straw, etc.) is 25-28MJ/kg, which is comparable to the commercial coal calorific value. In addition, bio-coal is environmentally friendly with stable performance, low sulfur content, and no heavy metals. Model research also shows that my country's biocoal production potential can reach 402 million tons of standard coal.

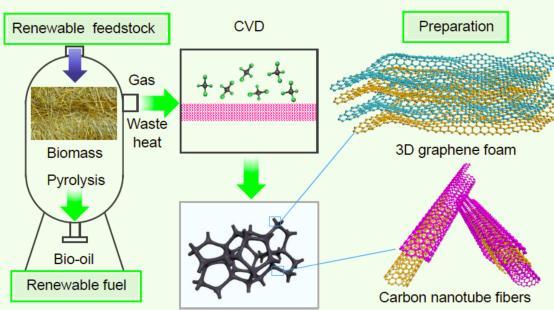

Schematic diagram of pyrolysis of waste biomass to prepare high value-added carbon nanomaterials

Except for bio-oil, the high-temperature gas generated during the pyrolysis process has not been fully utilized. The analysis results show that pyrolysis gas contains small molecules of carbon organic matter, and the pyrolysis gas temperature is higher, which is a potential precursor for preparing carbon nanomaterials. By optimizing pyrolysis conditions, researchers do not need to cool and purify pyrolysis gas. Not only can they use model biomass raw materials (lignin and cellulose) pyrolysis gas, but also can use waste biomass (sawdust and wheat straw) pyrolysis gas directly 3D graphene was prepared by chemical vapor deposition method. By changing the pyrolysis deposition conditions, carbon nanowires can be obtained. These high value-added carbon materials have demonstrated good performance in pollutant removal and energy storage. Compared with traditional graphene vapor deposition, the results of Life Cycle Assessment (LCA) show that the use of biomass pyrolysis gas to synthesize graphene has less environmental impact and energy consumption. Related research results were published in the journal Nature-Sustainability.

This research is of great significance to increase the value of waste biomass pyrolysis products and thus promote the commercialization of pyrolysis technology.